UV degradation is a commonly overlooked characteristic when specifying products meant for permanent outdoor installation. Using materials that have been subjected to UV “weathering” tests is vital for product longevity. Read on to understand better the fundamentals of ultraviolet light and how to select materials suitable for outdoor environments.

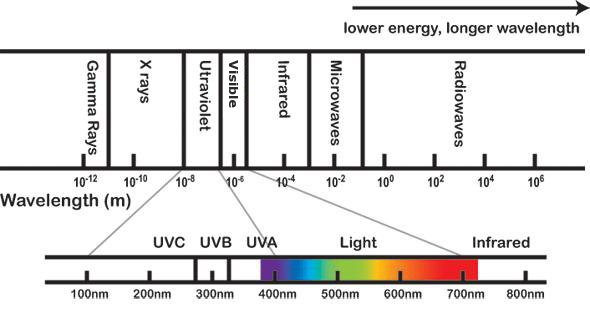

There are 3 different spectrum classifications for UV radiation. In essence, all UVC & almost all UVB is blocked by our atmosphere and ozone layer. However, UVA is hardly affected by ozone, and almost all of it reaches the Earth’s surface. Weather, temperature, humidity, and geographic location play a large role in regulating the amounts of UV energy received. But ultimately, everything on earth is affected by UVA (and just a bit of UVB) when exposed to sunlight.

Image: the electro-magnetic spectrum.

UV is electromagnetic energy, not far off from X-rays in the spectrum. So, it is relatively powerful radiation. UV degrades material by a process in which high-energy photons induce electrons in the atoms of other materials to higher levels of energy, leading to oxidation and other chemical reactions. This can break covalent bonds and, thus, long chain molecules like those in some plastics get broken up into smaller, weaker segments. Knowing this electron interaction, it can be understood why some materials are susceptible to UV-degradation and others not. For instance, metals, glass, and some acrylics are all mostly impervious to long-term UV exposure because of their atomic and molecular structure.

Where necessary, there are plastics available that resist UV very well. Fluoropolymers such as FEP and polyimides are plastics which have been successfully used in extra high UV environments, for example on the Hubble Space Telescope and the International Space Station. But for manufacturing purposes in more terrestrial based products, protective coatings and paint finishes are usually more cost-effective. Using UV stabilizers such as hindered amine light stabilizers (HALS), carbon black and titanium dioxide, UV degradation can be limited to achieve planned product lifespans.

There are a few standardized testing procedures to simulate accelerated solar aging such as in IEC 60068-2-5 Simulated solar radiation at ground level and guidance for solar radiation testing and weathering. But there is no single internationally used degradation “rating” system like the IP scale to judge or quantify UV resistance over time. One manufacturing standard for that is used with increasing frequency is UL 50E Enclosures for Electrical Equipment which includes an evaluation for resistance to degradation caused by UV light. Some manufacturers have now tested to UL50E to provide a measured level of performance against UV radiation. But for now, a widely used metric for UV resistance over time is usually not available when selecting products.

SGM approaches the complications of UV degradation on components in two ways; by utilizing top-quality UV and corrosion resistant coatings for parts that are exposed, and also eliminating as many vulnerable parts as possible. For example, the thin, clear plastic usually required on LCD user displays can be particularly vulnerable to UV degradation. These organic-based polymers undergo photolytic and photo-oxidative reactions during exposure to UV. The material becomes brittle over time, showing a chalky appearance and/or color shift on the surface. In extreme cases, microcracking can take place which threatens any water ingress protection. On SGM POI products, the user display is replaced by a simple LED status and control indicator which is rated for long-term exposure to UV rays. Programming and configuration are done via SGM software either wired or via wireless. Paint and coatings are then applied to exposed materials via spray, dip, and other processes like specialized silk-screening.

This is one of the reasons why SGM can offer a 5-year warranty - in any RAL color - when mounted in any outdoor environment. Something not offered by any other moving light manufacturer. Look for these vulnerabilities and product design choices when selecting products intended for outdoor installations.